My lovely daughter-in-law texted me an image a while back and asked if I could make her some organizers for canning jar lids. I immediately responded that of course I could! Then my laser broke. Sigh.

What should have been an easy project became a much lengthy one because I didn’t have a backup solution for cutting the 5mm plywood necessary for the project when my laser went belly up. I’d had a Glowforge for a few years and it died. Again. For the second time. The first time they managed to convince me that the right step forward was to purchase a refurbished model from them. I kick myself now, but I agreed. And the damn thing died a death exactly like the first one did. When I contacted Glowforge support to see what could be done, I’ll be damned if they didn’t trot out exactly the same solution. I could spend more money with them for another refurbished machine which would undoubtedly die a death in just another year and a half or two. Basically the camera uses a plastic tape bridge to connect to the main part of the machine. That plastic gets stressed each and every time the lid is opened and closed and, it’s clear now, that’s by far the most likely place for the unit to die. Twice. And, insult to injury, Glowforge won’t repair them and won’t allow anyone else to do it either. There is clear indication that if they figure out that someone serviced your laser, they will brick it.

Since I’m slow but not dumb, it was clear I needed a different solution, so I started looking. As a retired Maker on a budget, I eventually settled on an OmTech Polar 350. Is the end-all and be-all of laser engraver/cutters? Nope. The fish-eye camera can be corrected to some extent, but it’s still fishy around the edges of the cutting area. Second (so far), the machine has to be driven directly by a laptop or computer (not simply Wireless, as the Glowforge could be), meaning I have to have the laptop I use to control my CNC near the cutter when I’m using. Like really close. Because if I want to go the roughly 10′ from the laser to the computer I use in the kitchenette part of my shop, it won’t work, the signal gets degraded to the point where the camera is not detected. So, the laptop has to be within a few feet to use the USB cable that came with the machine. I even tried something called an “active repeater cable” and didn’t seem to do anything useful. So, it works, but without spending quite a bit more, I think I’m going to have to get used to this as a solution, since I don’t seem to want to try and make money with it to afford an upgrade.

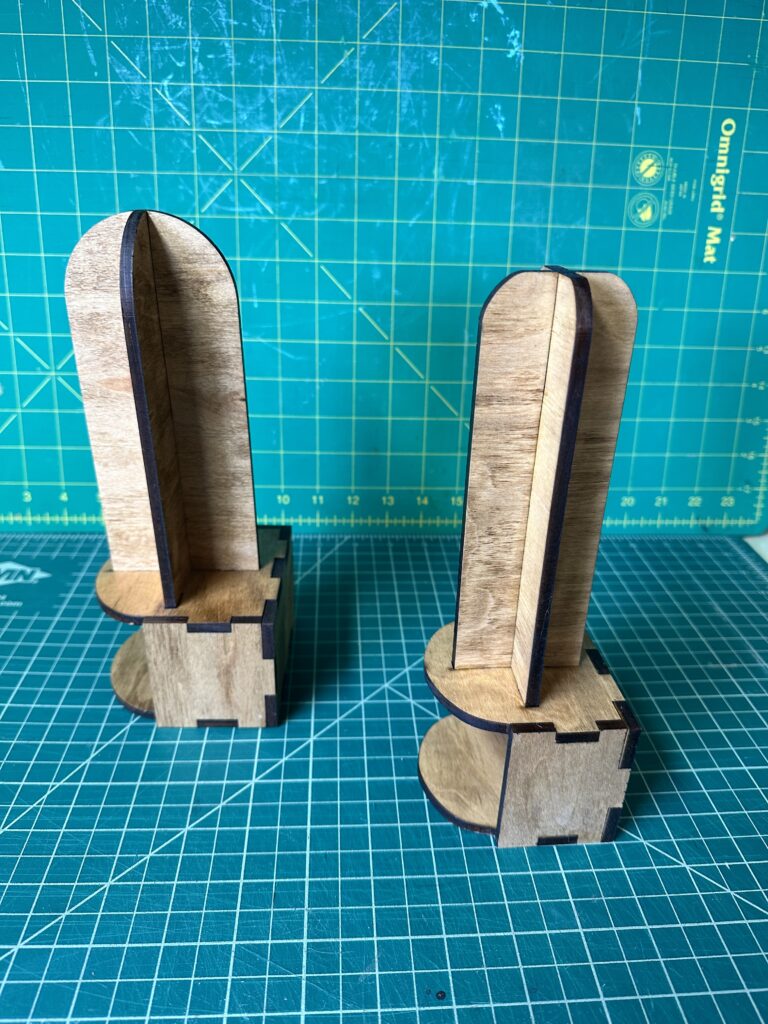

Anyway, long story short, I found a cutting pattern on Etsy for the normal and wide-mouth jar lids, purchased that and cut three each of the normal and large and I’ll happily hand those over to her in a week and a half!

In theory, I could have replicated these plans since I didn’t plan on selling the product, but even my time is money and the cost of the plans made the decision to purchase the plans a no-brainer.

I pre-stained the material, glued up the results and then each got three coats of polyurethane to protect them.

And then I called it good.

0 Comments